In today’s market, paint protection film (PPF), or often referred as “Clear Bra” has become a popular technology that protects painted surfaces of a new or used vehicle. Many films in the market are thermoplastic urethane and feature a “self-healing” effect which are used to prevent rock chips, bug splatters, tree saps, and most importantly minor scratches and swirl marks. PPF is typically installed on surfaces labelled as high impact areas, such as the front bumper, hood, fenders and side mirror caps.

PPF is a clear film that is installed on painted surfaces to provide physical protection, but still allowing the high gloss finish from the paint to be seen. Not only does PPF prevents and reduces of paint damages from physical contact, but it is also resistant to acidic contacts, corrosion, and the reduction of oxidation from UV (Ultraviolet) light-rays from the sun.

How is PFF installed?

Cutting the Film to the exact fit

As each panel on every vehicle is different, it is important to get the exact fitment for a flush installation. Many film manufacturers provide digital designs for most new vehicles, which will be translated into a digital plotter for the exact cut. This method is often referred as the “Pre-Cut Install”.

The alternative method is to lay a bulk roll of film onto the surface, and hand trim the edges accordingly. This method requires extreme accuracy during the trim for a “perfect” install. There is also certain risks involved with the “bulk” install method as the installer is putting a knife on the vehicle to make every cut.

Preparing the Vehicle for Film Application

In order to achieve a satisfactory installation, a deep thorough clean of the vehicle is mandatory. The painted surfaces will have to be free of any road tar, adhesive, tree saps, bugs, and any other residues prior to install. Any remaining debris will cause issues during the installation process.

Aligning the Film onto the Painted Surfaces

A soap mixed water based solution commonly known as “slip” is used as a wet application for PPF installation. The solution is applied between the film and the paint to allow the film to freely move. This allows the installer to easily position the film on the surface for an accurate install.

Securing the Film

After the film has been positioned correctly, the installer will use a “tact solution” to lock the film into place. The “tact solution” is an isopropyl alcohol mixed water based solution that activates the adhesive under the PPF. An applicator squeegee is used to squeeze out any liquids and air pockets between the paint and the film, which will allow the adhesive to bond to the paint. Heat is typically applied with an industrial heat gun to the edges to ensure 100% bonding. For curved edges and “wrap-around” edges, an adhesive primer is often used to promote adhesion to ensure the film does not lift over time.

Maintenance for PPF

After installation, car washes should be avoided for approximately two weeks to ensure that the PPF adheres to the paint surfaces. Any water along the edges before the adhesive fully cured may cause the film to lift, which would be costly to repair (if not a full replacement). Professional installers would very often recommended using pH neutral car shampoo to ensure the longevity of the PPF.

Professional Installers

There is a lot of automotive products on the market that are available as an DIY option, but PPF installs would not fall under that category as it requires a lot of specialized techniques and experiences. The top tier PPF manufacturers will provide a list of authorized dealers to ensure their products are installed to the highest level of standards. Also, most warranties provided by the manufacturers are only warranted if their products are installed by a recognized partner of theirs. To ensure you pay for what you purchase, always ensure the installer you are working with is an authorized outlet and installer of the PPF you are buying.

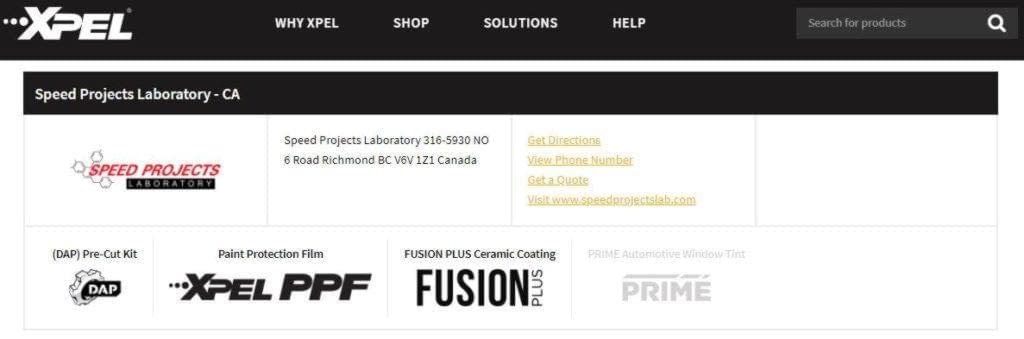

Speed Projects Laboratory

At Speed Projects Lab, our PPF installers are factory certified by the film manufacturer XPEL. We are equipped with a computer plotter to plot out exact designs from XPEL’s design program called DAP for your vehicle. Unless the bulking method will yield better results, all installs are done using the Pre-Cut method to ensure we minimize knife use on the vehicle. For more information, feel free to head over to our dedicated “XPEL Paint Protection” page.